Creating Demand For Captured Carbon: The Unsolved Puzzle

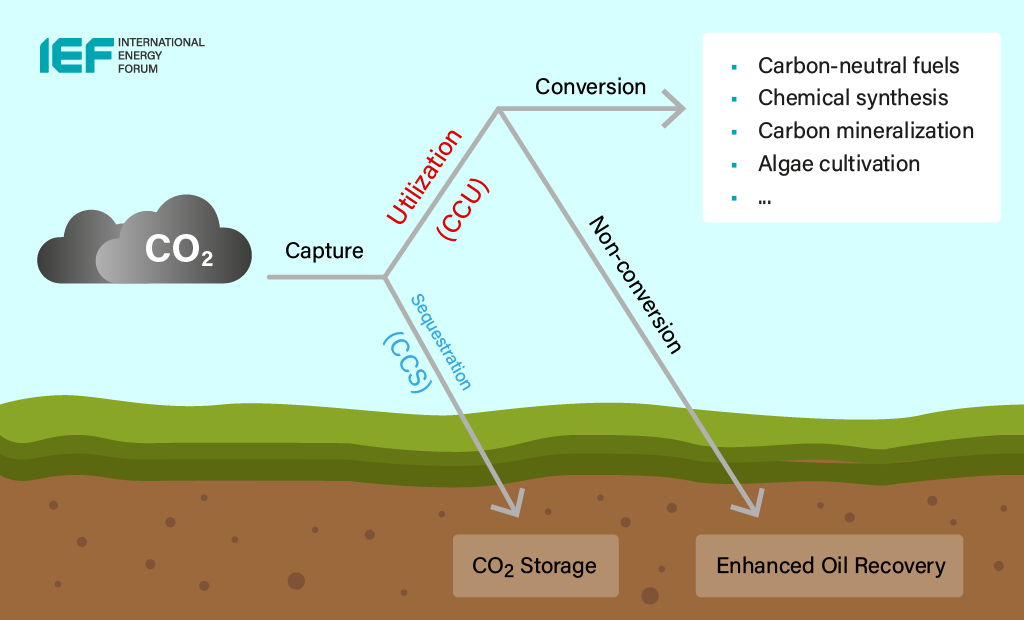

Carbon capture, utilization, and storage (CCUS) is considered a critical element of climate action, although the technology is yet to be deployed at scale. Creating demand for the supply of carbon dioxide (CO2) would provide commercial incentives to invest in CCUS.

An essential technology

CCUS involves capturing carbon dioxide at the source and using it in industrial processes and/or storing it indefinitely. According to an IEA analysis which takes into consideration existing and planned infrastructure projects, CCUS must be hugely expanded to offset excess carbon emissions. Around 40 million tonnes (Mt) of carbon are captured each year; the Global CCS Institute estimates this must expand to 5,600 Mt by 2050. IEA's Clean Technology Scenario, which maps out a pathway consistent with Paris Agreement targets, suggests that CCUS – among the most cost-effective ways of reducing industrial emissions – could contribute almost one-fifth of industrial emissions reductions.

While CCUS is among the most cost-effective solutions for large-scale emissions reductions in some industrial processes, carbon capture has not yet been deployed at scale. Investors still question whether it can be profitable. Last year, the largest power-generation CCUS project was shelved.

Meanwhile, carbon remains a desirable commodity thanks to its unique properties; its many applications include use as a solvent, a cleaning agent, and a chemical building block. To meet demand, more than 220 Mt of CO2 is extracted for use each year: both as a by-product of industrial processes and as a commodity unearthed from naturally occurring underground reservoirs. Bridging the gap between CCUS and carbon demand could unlock the technology's vast potential to support climate goals by displacing a product that would produce higher emissions over its life cycle, as well as by driving investment in carbon capture.

Carbon as a commodity

CO2 has many industrial uses: it can be consumed in a pure state, transformed into fuels, or converted for use in chemicals and building materials. Its uses range from food and drink production to metalworks.

In agriculture, carbon dioxide is combined with ammonia to produce urea: an essential synthetic nitrogen fertilizer for supporting intensive agriculture. Already, 120 Mt of CO2 feedstock is used each year in urea manufacturing, making it the most prevalent use of carbon.

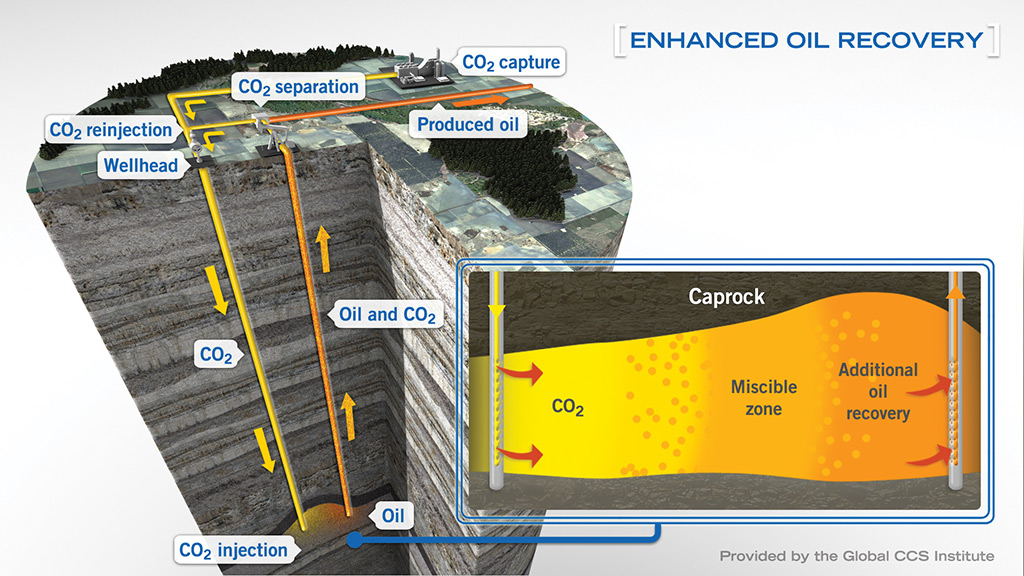

Another prevalent use is in the oil sector, which uses 70-80Mt of CO2 each year for enhanced oil recovery (EOR). EOR involves injecting CO2 and water to displace crude oil which would be impossible to extract otherwise. Natural gas processing facilities such as Shute Creek in Wyoming have adjoined carbon capture projects, resulting in millions of tonnes of CO2 being captured and repurposed for EOR annually.

CO2 is also used to produce all sorts of chemicals, including plastics, fibers, and synthetic rubber. For instance, it can be converted to methanol or methane, which is then turned into intermediates for manufacturing plastics or into aromatics for manufacturing personal care items. While many uses of CO2 still end up releasing carbon as emissions, chemical production can ‘lock' carbon into items, functioning as both carbon utilization and storage.

Even when CO2 is not sequestered in a new product, it can create environmental benefits by replacing a higher carbon equivalent.

Bridging the carbon gap

The CO2 use market is unlikely to scale significantly in the short term. Commercial barriers present a larger problem than technical barriers, so external support is necessary to drive its development and deployment, experts believe.

In some areas – such as in building materials production – CO2-derived products are already competitive. However, this is the exception rather than the rule, and using captured carbon can come at a great cost. For instance, using captured carbon rather than conventional fossil fuels in chemicals production multiplies costs.

Some private actors are helping stimulate CCUS innovation, such as the $100m XPRIZE Carbon Removal competition, funded by entrepreneur Elon Musk. However, the scale of the challenge also calls for government intervention to make captured carbon more commercially attractive: policies could range from carbon pricing adjustments to public procurement of carbon-derived products to create early markets. The IEA also calls for the development of industrial CCUS hubs with dedicated CO2 transport and storage networks to reduce unit costs through economies of scale.

Of course, utilizing captured CO2 does not always result in negative emissions or even reduced emissions; quantifying its benefit is a challenging task requiring full life-cycle assessment.

Carbon use is best considered as a complement – not a replacement – for carbon storage and emissions-reduction action, playing an important role as part of an ‘all technologies' approach to climate mitigation.